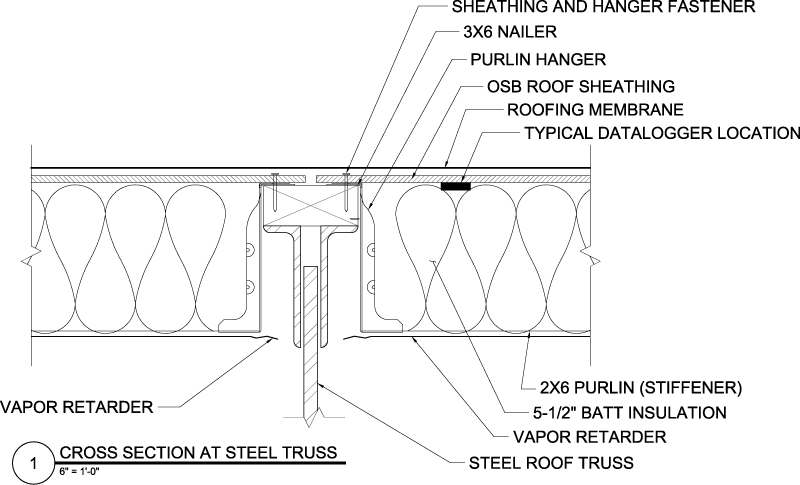

Proper placement of a vapor retarder to manage the vapor drive and proper detailing to prevent air infiltration or.

Roofing refrigerated storage without vapor seal.

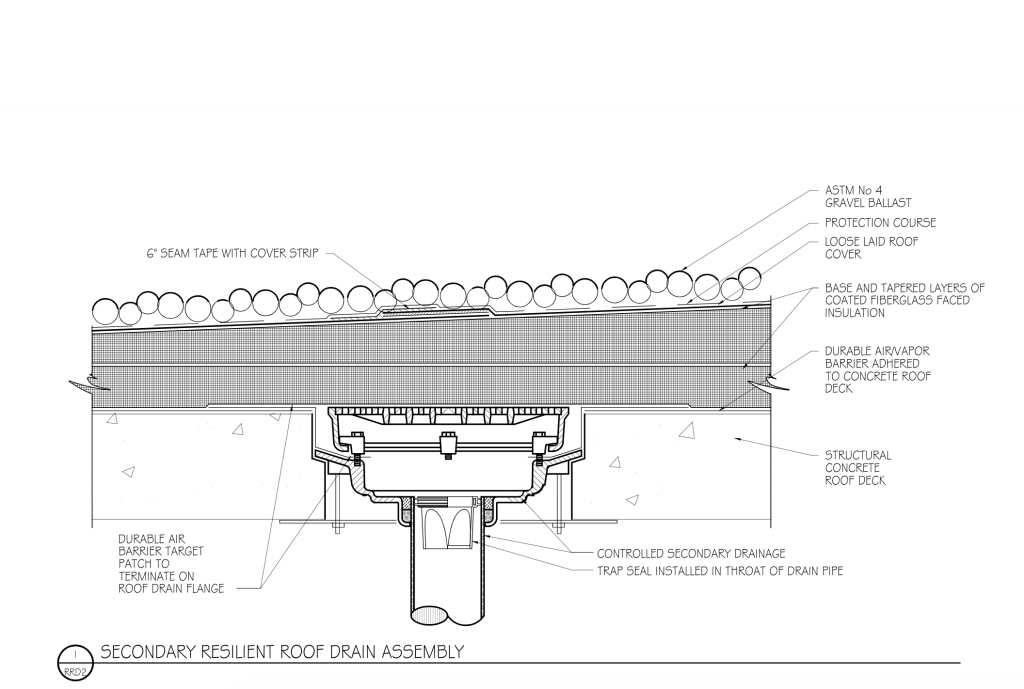

Adhered mechanically fastened or ballasted roofing assemblies that incorporate epdm tpo or fleeceback membrane.

Without a complete vapor seal vapor drive will result in condensation or ice formations at the building interior what follows are general details provided by metl span showing typical cold storage imp vapor barrier installation steps.

Vapor tight and energy efficient roof systems are a specialty requirement.

2 internal floating type cover.

The cold storage freezer envelope system consists of.

In this situation the water vapor on the outside of the building will by vapor pressure differential move into the cold storage building s interior.

Roofing shingles and materials plus factory certified roofers including ratings from real homeowners from north america s largest roofing manufacturer.

There are a number of variables to juggle when designing and building a cold storage warehouse including.

Generally speaking a roof is designed to keep the interior of a building dry and safe from the elements.

Residential and commercial roofing shingles slate roof ventilation roof underlayments asphaltic and tpo roof membranes.

It should be installed in layers with staggered joints at both the slab and the roof to prevent easy transmittance of temperature.

The kaiser martin group is the premier cold storage builder and refrigerated warehouse builder for the northeastern u s.

Concrete floor fabrication insulation systems cold storage doors and vapor barriers.

We provide solutions for fresh food and frozen foods including ammonia refrigeration blast freezers walk in freezers and freon.

If the vapor barrier is not installed properly or does not have a complete seal moisture vapor will penetrate into the building and over time ice will begin forming and expanding.

The building location s annual outside temperatures plays a role in determining insulation thickness both for walls and roofs.

Provide proper insulation at freezer slabs.

For coolers and freezers the roof exterior vapor barrier whether imp or membrane must tie into the imp wall at roof to wall connections.

This requires two critical measures for roof design.

In the primary seal envelope surrounding the annular vapor space enclosed by the roof edge seal fabric and secondary seal.

Moisture flow and vapor retarders.

In cold storage facilities moisture vapor flow is reversed from a traditional building in a northern climate including the roof.

F any emergency roof drain shall be provided with a slotted membrane fabric cover or equivalent device that covers at least nine tenths 9 10 of the area of the opening.

Achieve an uninterrupted or continuous vapor seal and obtain the applicable carlisle roofing and vapor seal warranty.

When designing the roof of a cold storage building a major concern is the significant vapor drive that occurs predominantly from the warmer exterior toward the colder interior.